This site uses cookies or similar technologies for technical purposes. In addition, with your consent, your information may also be used for other purposes as specified in the

cookie policy. You can freely give, refuse, revoke your consent or customize your preferences at any time, by clicking on the “Set your Cookie preferences”. By clicking on the "Accept All Cookies", you consent to the use of your data for all the purposes indicated. By clicking “Refuse cookies", you will continue browsing without accepting unnecessary cookies.

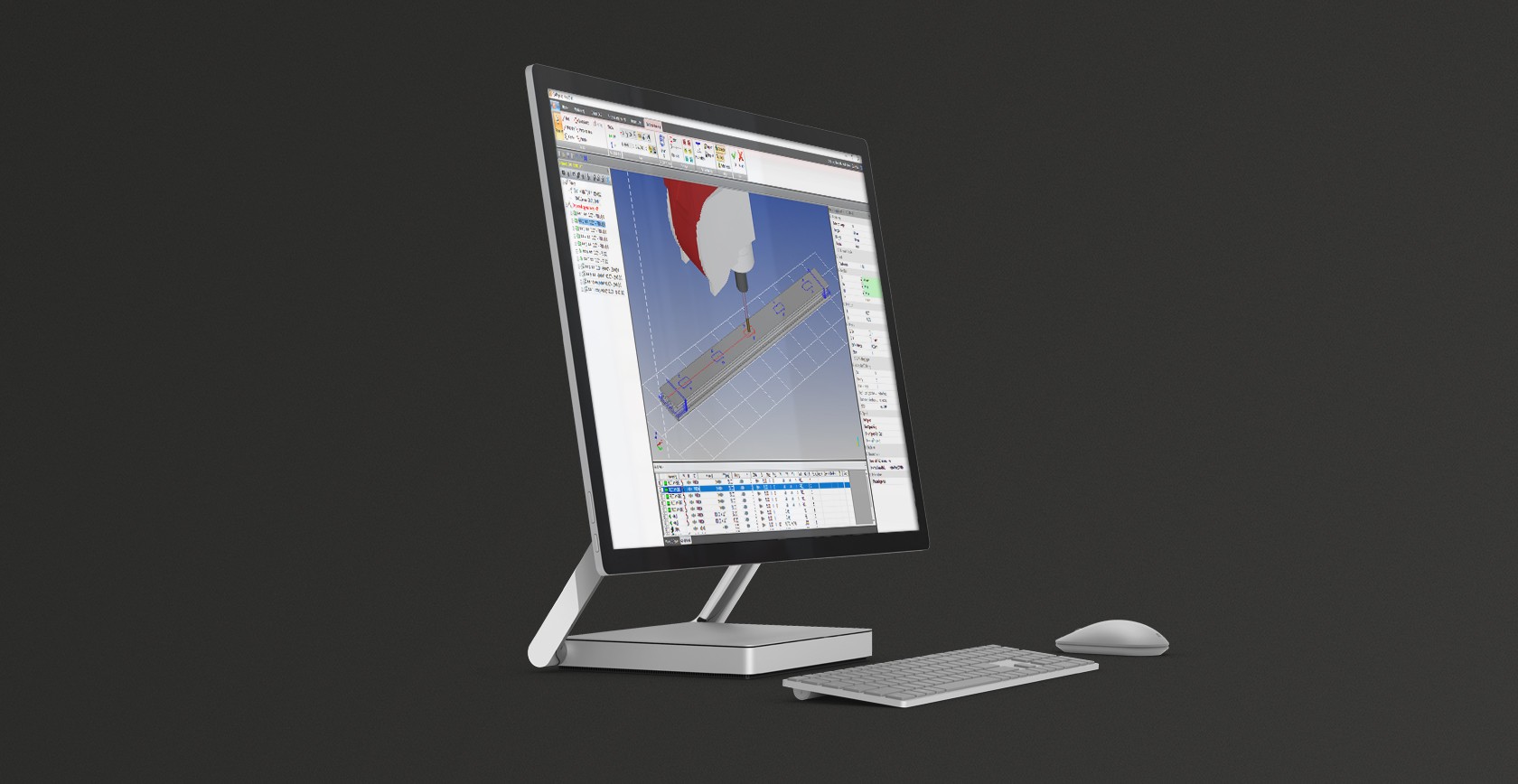

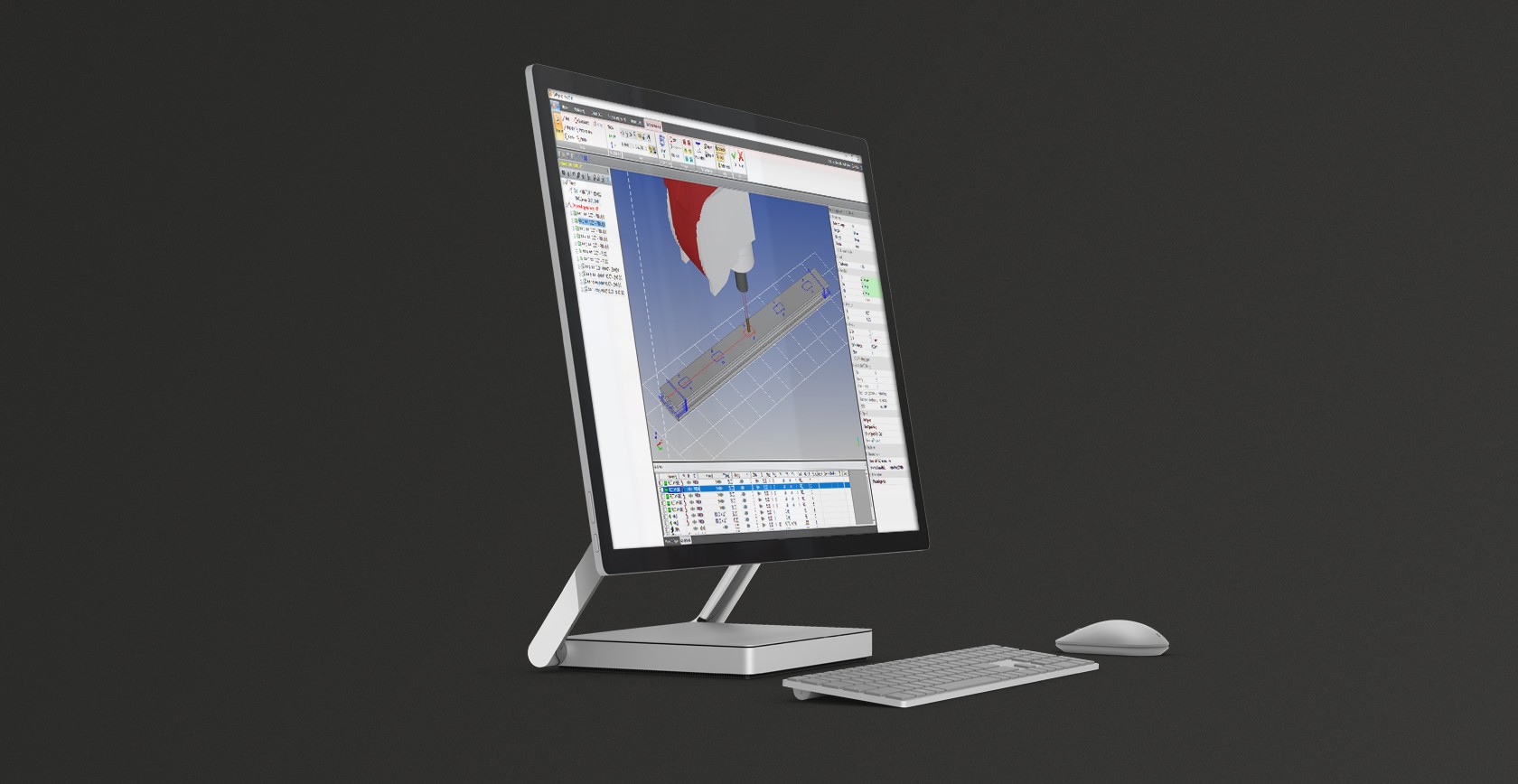

open video

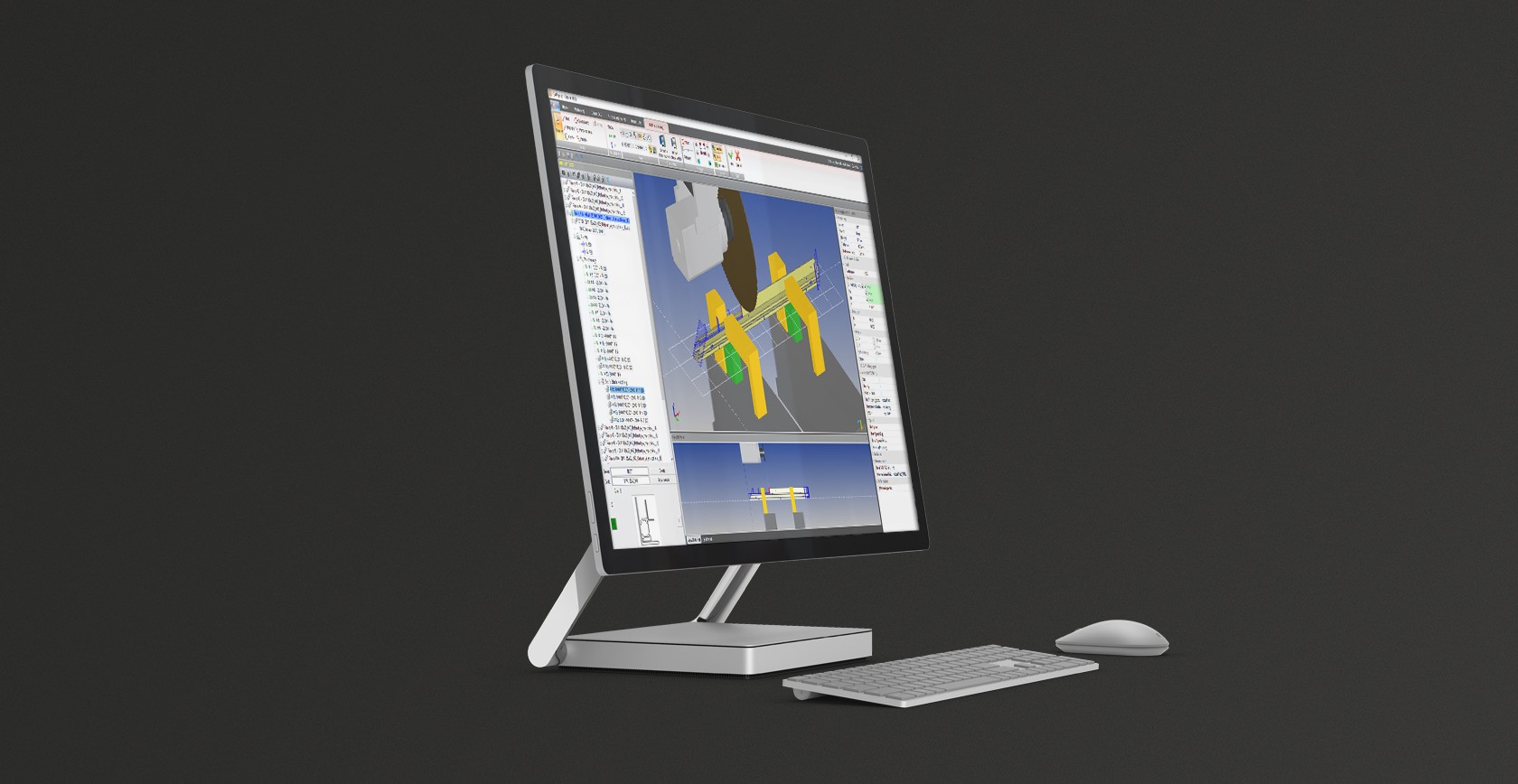

open video